We are currently teaming with a design group on a complex adaptive reuse of an existing 80,000 sf facility. During this pre-construction phase, we conducted a fair amount of interior demolition and are evaluating existing conditions so that we can compare those conditions with the initial design drawings in order to identify issues.

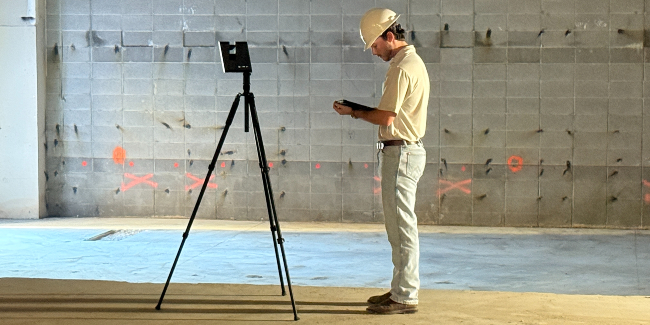

We are using Matterport which uses Lidar technology to produce 3D models of the existing physical spaces. The result is a “digital twin,” or a virtual version of a physical space, that the design firm can then use to assist in preparation of working drawings for the new build. With this particular project, we set up in each area of the building and recreated the space digitally showing all existing features in detail. This technology also allows us to take precise measurements to be used during the design process. Here are a few benefits we are seeing:

- More accurate layout of fixtures and furnishings

- Identifies potential problems with existing openings and clearance issues

- Produces a BIM file that can be used for design

- Reduces travel needs by design team

- Enhances collaboration between the OAC team

- Minimizes costs of issues found during construction

The number one benefit of producing these models is the ability for us to work with the design team to identify “clashes” between the existing facility and future design so that accurate design drawings are produced. This minimizes or eliminates unforeseen problems that can result in additional costs and delays during construction. We are currently using this method on several of our projects and seeing solid results.